Double-sided FPC Flexible Coil PCB

Double-sided FPC Flexible Coil PCB

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Piece/Pieces |

| Packaging: | Vaccum Package |

|---|---|

| Productivity: | 10000 |

| Brand: | JHY PCB |

| Transportation: | Ocean,Air |

| Place of Origin: | China |

| Certificate: | ISO9001 |

Product Description

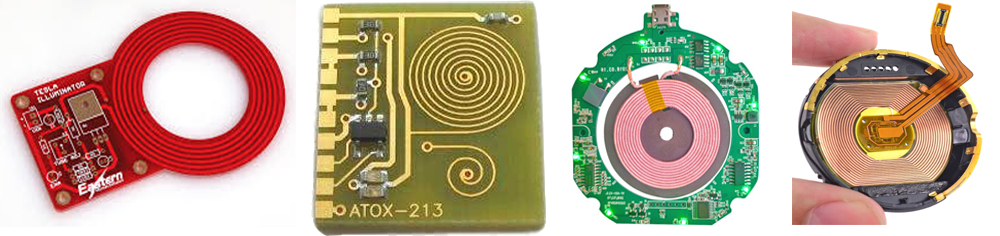

Double-sided FPC Flexible Coil PCB, PCB Coil, Double Sided Flexible PCB Fabrication Manufacturing and Supplier.

What Is Coil PCB,PCB Coil?

The circuit pattern is mainly wound, and the circuit board is replaced by an etched circuit instead of the traditional copper wire. It is mainly used in inductor components and has a series of advantages such as high measurement accuracy, good linearity, and simple structure.

Double Sided FPC Coil PCB

Have you heard of the modularized circuit board and programmed module? The so-called modular circuit board is a collection of units that can realize certain functions. If these modules are made into a circuit board, they will become a module circuit board. For example, the display board and the power board can become a module board. For air conditioning, AD / DA module, clock module, etc., they can be made into a separate circuit board, which can be inserted into the main control board for application. In this way, for different specifications of air conditioning, if the power modules are the same, you can use the same model of the power circuit board, without redesign, which can reduce costs.In comparison, the coil circuit board is more portable, small in size and light in weight, with an open coil, convenient in access and wide in a frequency range. From the drawing, the coil board has a very obvious difference, there are a lot of winding like fingerprints.

Coil circuit boards are mainly used in wireless chargers, Calculator, sensors, etc.

Moreover, due to the unique advantages of the flexible circuit board, the coil PCB is generally also made of a flexible PCB.

Learn more about JHY PCB by exploring the manufacturing capability of Flexible PCB below. We can do more than you can imagine.

| Items | Manufacturing Capability | |

| PCB Layers | 1 - 8layers | |

| Laminate | DuPont PI, Shengyi PI | |

| Maximum PCB Size(Length x Width) | Single Sided PCB | 480*4000mm |

| Double Sided PCB | 480*1800mm | |

| Multilayers | 236*600mm | |

| Minimum Board Thickness | Single Sided PCB | 0.05mm+/-0.02mm |

| Double Sided PCB | 0.08mm+/-0.02mm | |

| Multilayers | As per Gerber | |

| Finished Board Thickness | 1-6L | 0.05mm-0.6mm |

| 8L | 1.6mm | |

| Min Tracing/Spacing | Copper Thickness 1/3 oz: | 0.076mm/0.076mm (1-6L) |

| 0.05mm/0.05mm (8L) | ||

| Copper Thickness 1/2 oz: | 0.076mm/0.076mm (1-6L) | |

| 0.06mm/0.06mm (8L) | ||

| Copper Thickness 1oz: | 0.1mm/0.1mm (1-6L) | |

| 0.065mm/0.065mm (8L) | ||

| Min. Annular Ring | 4mil | |

| Minimum Hole Size | 1-6L | 0.2mm(8mil) (CNC) |

| 8L | 0.15mm(CNC) | |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | |

| Solder-stop coating---Coverlay | PI and PET film | |

| Silkscreen Color | White, Black, Yellow | |

| Surface Finish | OSP | |

| e HASL | ||

| ENIG(Electroless NickLead-Freeion Gold) | Ni thickness:2-6um | |

| Au thickness:0.025-0.05um | ||

| Flash Gold | Ni thickness:2-8um | |

| Au thickness:0.025-0.15um | ||

| Immersion Tin | Tin thickness:0.5-1um | |

| PlatingTin | Tin thickness:1-10um | |

| Laser cuPunching | ||

| Special technologies | Peelable solder mask | |

| Gold fingers | ||

| Stiffener (only for PI/FR4 substrate) | ||

| Impedance Control+/-10% | ||

| Rigid Flex PCB | ||

Advanced Features for Flexible PCB

As the flex circuit market continues to expand, there have been many advances in technology including:

Heat Sinks – Heat sinks can be laminated to flex circuits to dissipate heat away from sensitive components such as LEDs.

Component Assembly –We offer through hole and surface mount capabilities, as well as in circuit testing, conformal coating, and electrostatic protective packaging.

Controlled Impedance – With increasing signal switching speeds, engineers need to understand and control the impedance of traces. With short signal transition times and high clock rates of modern digital circuitry, traces need to be considered transmission lines instead of simple interconnections. With today`s higher speed requirements, controlled impedance traces are designed to minimize electrical reflections and ensure an error free transition between the track and interconnections. If perfectly optimized, controlled impedance allows control of the physical dimensions and material of the cable. Controlled impedance signal transmission requires flexible circuit materials to be uniform in both thickness and electrical properties. At Flexible Circuit Technologies, we have extensive experience in designing and manufacturing flex circuits with controlled impedance.

Crimp Pins – Crimp Pins are mechanically attached a circuit to allow for soldered connections.

Graphic Overlays – Graphic Overlays can be placed over flexible circuits, rigid boards or membrane switches. The overlays provide the user interface with the underlying circuit and typically are used in conjunction with LEDs, LCD displays or dome switches mounted on thie circuits. The overlays are made from polycarbonate, polyester or acrylic materials.

Laser Skived Slots and Holes – Historically, X-acto knives or razor blades were utilized to cut intricate areas of a flex circuit, the successful yield of which depended on the skill of the operator. FCT has dramatically improved this process by utilizing a top-of-the-line laser beam with extremely precise depth control to accurately cut the underlying substrate of a flex circuit. Precise laser beams can skive circuit openings with the utmost precision.

Overmolding – Overmolding is the process by which FCT embeds electronics versus simply placing electronics on the circuit. As electronic devices and required interconnections become more compact, embedding electronic circuitry within the cable assembly is a cost effective alternative to on-board electronics. Most often referred to as smart cables or dongles, these embedded devices can solve many packaging challenges.

Panelization – During the panelization process a stiffener is applied to the boundaries of multiple circuits on a panel so that they can be easily processed through the [pick & place" and wave soldering processes. Once the panel of circuit boards is done, simply clip them out and they are ready to go.

Pressure Sensitive Adhesives (PSAs) – PSAs with a release liner are used in applications where a portion(s) of the circuit needs to be secured to a specific location within the final product. During assembly, the release liner is peeled away and the exposed adhesive allows the assembler to press the circuit into place and keep it there.

Sculptured Flex Circuits – Sculptured flex circuits are special in that the copper conductors vary in depth and thickness in different places. The copper is thin at the most flexible part of the circuit and thick at the interconnection point. Sculptured flex circuits allow for bare metal connections (like a plug in) and remain strong at the solder joint formation. Sculptured fingers provide a more reliable alternative to mechanically fastened crimp pins.

Shielding – Shielding is applied when an application requires limits in electromagnetic and/or electrostatic interference. Protective shielding can be patterned or solid. Either way, it reduces noise and controls impedance of signal lines.

Stiffeners – Stiffeners are applied to flex circuits where additional support is needed such as areas of component assembly or underneath exposed traces that will be plugged in for connection. Common stiffeners are FR4 and polyimide.

Wire Assembly – In certain applications a combination of flex or rigid circuit with traditional wire may be a more economical design that still meets the needs of the customer`s subassembly. At Flexible Circuit Technologies, we have the capabilities to design, source, manufacture and assemble the entire subassembly incorporating the circuit, wiring and components. This level of capabilities and commitment is what differentiates us from other flex circuit suppliers.

Flexible Heaters – Flexible heaters are thin, bendable heating elements, shaped to fit your unique heating equipment needs.

Hot Bar Solder – Hot bar solder connection is a way to eliminate a connector set between the hardboard and the flex circuit. This connection provides an efficient, durable and less expensive alternative to a standard connector set.

Product Categories : Flexible PCB

Hot Products

Tower Down Conductors for lightning and earthing protectionACSR Aluminum Bare Conductorlightining conductorFlexible Copper Stranded Conductor usd for transformerPE PVDF color coated aluminum coil for roofing decorationFactory Price 1050, 1100, 3003 Stucco Embossed Aluminum coil1235 aluminium foil paper for cigarette packing8021 Cold Forming Aluminum Foil for Pharmaceutical Packaging1060 aluminium strip for transformer1050, 1060 aluminum circle for deep drawing cookwareHigh conductivity and Better corrosion resistance aluminium foil for pharmacy usageUnderfloor heating; radiant heat transfer platealuminum trailer flooring8011 Hot Sale Materials for Bottle Cap Trailers Aluminum coil Capchina aluminium manufacture roll coated prepainted aluminum coil/prepainted aluminum sheet in coilaluminium sheet fabrication/aluminium sheet deep processing for punching